Author: Ben Selwyn | Posted On: 12 Jan 2026

Ask most automotive distributors how they handle supplier price increases, and you’ll hear some variation of ‘we negotiate hard and pass through what we can’t absorb.’ It sounds pragmatic. Commercially sensible. The challenge is that this approach assumes both parties are working from comparable information. Increasingly, they’re not.

The distributors who maintain healthy margins aren’t necessarily better negotiators. They’re better informed. They understand container rates, currency movements, raw material price cycles, and supplier cost structures well enough to distinguish between legitimate cost increases and margin expansion dressed as pass-through.

The information asymmetry problem

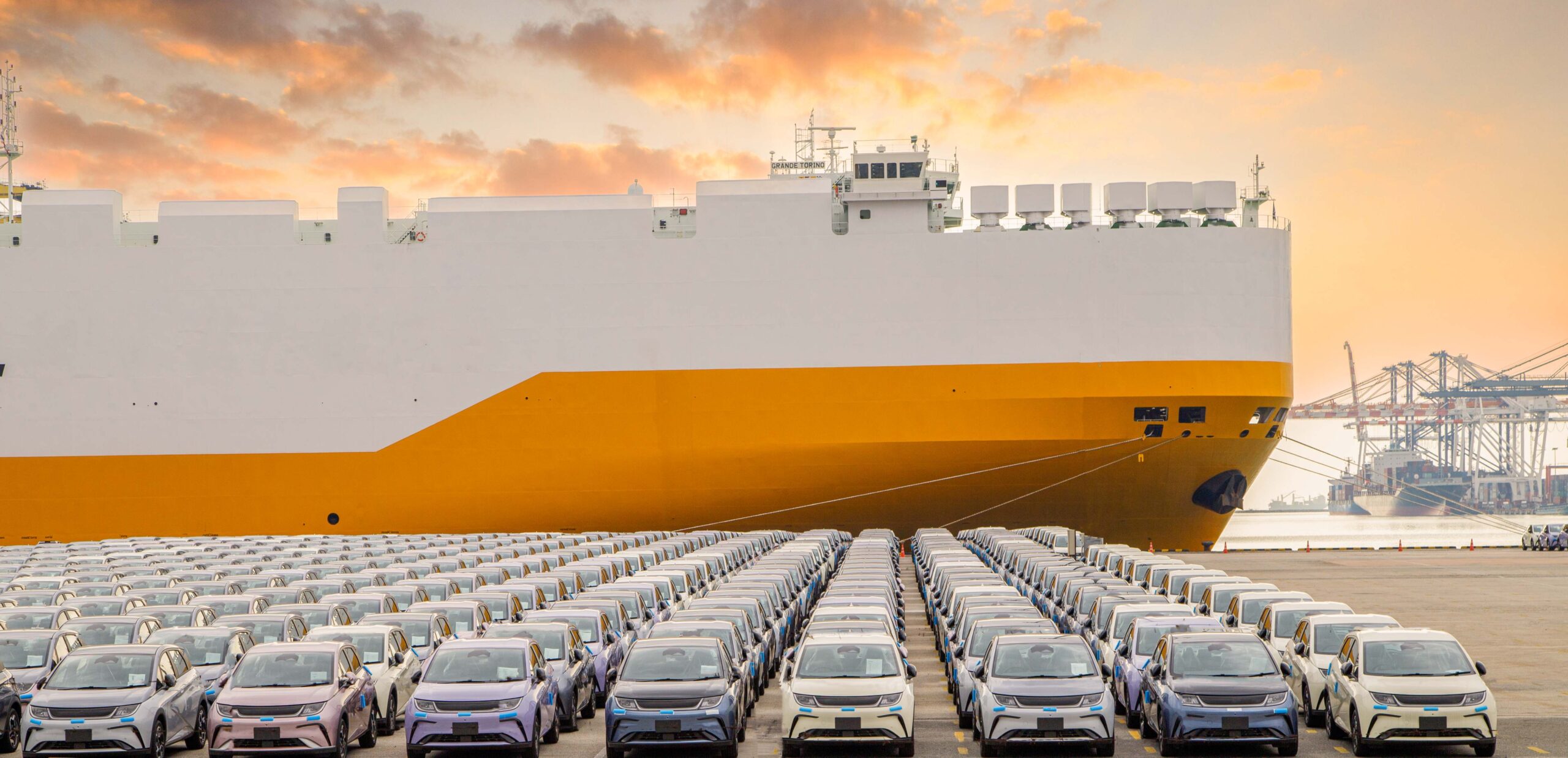

When shipping disruptions hit in 2021-2022, distributors received price increase notifications from suppliers citing freight cost escalation. Container rates from Asia to Australia increased substantially, with some routes seeing costs multiply several times over. The question facing distributors: was the supplier’s proposed price increase justified by actual landed cost changes?

Distributors who tracked container spot rates could calculate whether supplier increases matched actual freight cost movements. Those who understood container capacity and product packaging density could convert per-container freight increases into per-unit cost impacts. Those who monitored currency fluctuations could separate freight-driven cost increases from exchange rate effects.

This visibility created leverage. The distributor who accepted a supplier’s price increase because ‘freight costs were up’ paid more than one who calculated the actual landed cost impact and negotiated from data.

Beyond freight: raw material and tier-n visibility

Freight costs are however only one input to supplier pricing. For automotive consumables, raw material economics often drive larger cost movements. Base oils for lubricants track crude oil derivatives. Ethylene glycol for coolants follows petrochemical feedstock cycles. Brake fluid components have their own commodity price dynamics. Distributors who track these upstream inputs can anticipate pricing changes before suppliers announce them.

This also extends to Tier-2 and Tier-3 supplier visibility. Your suppliers source components from their own suppliers, who in turn source raw materials from commodity producers. Understanding this value chain reveals where cost pressures originate and how they flow through to your purchase prices. When ethylene glycol prices spike due to capacity constraints, coolant pricing will follow. The distributor who tracks feedstock markets can adjust purchasing timing and inventory positions accordingly.

This doesn’t require building a commodities trading desk. It requires systematic monitoring of price indices for relevant raw materials, understanding which inputs affect which product categories, and correlating historical supplier pricing behaviour with upstream cost movements. The data is largely public. The value comes from connecting it to your specific product portfolio.

Three questions worth asking

Before investing in upstream intelligence capability, it’s worth honestly assessing current position.

- How would we know if a supplier’s price increase exceeded actual cost movements? If the answer involves accepting supplier explanations at face value, there’s an information gap. If the answer involves back-of-envelope estimates without systematic data, there’s a capability gap. If the answer involves landed cost models updated with real-time freight, currency, and commodity data, you’re ahead of most competitors.

- Do we understand the raw material inputs for our major product categories? For lubricants, it’s base oil economics. For coolants, ethylene glycol. For brake fluids, glycol ether derivatives. Knowing these connections allows you to anticipate cost movements rather than react to supplier notifications.

- Do we have the internal resource to build and maintain this visibility? Upstream intelligence requires ongoing attention. Freight rates shift weekly. Currency moves daily. Commodity prices follow their own cycles. Someone needs to track the data, maintain the models, and translate movements into procurement decisions. If that resource doesn’t exist internally, external options are worth considering.

Build versus buy

There are two paths to upstream visibility. The first is building internal capability: dedicating analyst time to tracking freight indices, commodity prices, and currency movements, then correlating this data with supplier pricing behaviour over time. The advantage is institutional knowledge that accumulates. The challenge is resource allocation and the time required to establish baseline models.

The second is engaging specialist providers who deliver supply chain intelligence as a service. Firms operating in this space offer commodity price tracking with historical data and forecasts, supplier cost modelling, and risk assessment across the value chain. They maintain the data infrastructure and analytical capability, delivering insights on a subscription or project basis.

For many distributors, a hybrid approach makes sense. Use external providers for broad commodity and freight intelligence (where scale matters and data sources are standardised), while building internal capability for supplier-specific cost modelling and competitive intelligence (where proprietary knowledge creates advantage). The key is being deliberate about which elements sit where.

Where to from here

The distributor who operates without upstream visibility pays more for products, accepts supplier narratives without validation, and makes procurement decisions reactively. The distributor who builds supply chain intelligence capability (whether internally, externally, or through a combination) negotiates from data rather than assumptions and anticipates cost movements before they arrive.

With that said, building this capability takes time. You need to identify relevant data sources, establish baseline cost structures during stable periods, and track how your suppliers historically respond to cost movements. Whether you build or buy, the infrastructure doesn’t appear overnight.

The distributors who start now will have information advantage when the next disruption arrives. Those who wait will negotiate from the same position they always have.

Fifth Quadrant works with automotive distributors and aftermarket businesses on market intelligence and strategic positioning. Click here to read our recent article on how companies can use market research to understand customer willingness to pay, and if you’d like to explore what supply chain visibility could look like for your business, contact our team.

Posted in Auto & Mobility, B2B, Uncategorized